Suriname Solder ball jet laser soldering machine

Category:

SurinamePrecision laser welding

Product Description

Product advantages:

The heating and droplet process is fast and can be completed within 0.2s.

Complete solder ball melting in the solder nozzle without spatter

No flux is required and no pollution is required, and the minimum diameter of solder balls for the service life of electronic devices is 0.1mm, which conforms to the development trend of integration and precision. The welding quality of different solder joints can be stable and the yield rate is high through the selection of solder ball size.

With CCD positioning system suitable for assembly line mass production requirements

Application areas:

Can be used for wafer, optoelectronic products, MEMS, sensors, BGA, HDD (HGA, HSA), mobile phone communications, digital cameras, camera modules and other high-precision components welding, etc.

|

|

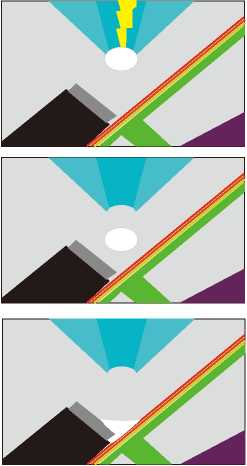

The solder ball automatically rolls into the nozzle, and the nozzle is stuck with the unmelted solder ball. The nozzle starts to fill with nitrogen. |

| When the nitrogen pressure reaches the preset value, the laser irradiation starts, the solder ball melting process starts, and the solder ball is sprayed under the pressure of nitrogen. | ||

|

The solder ball contacts the pad to form a bump, and the pad does not need to be preheated. |

Working principle:

Two different heating principles:

What is the difference between laser welding with surface heating and soldering iron welding with "heat transfer?

The welding process is divided into three basic steps: "preheating" the welding part of the soldering iron, "heating" when providing solder, and "post-heating" when providing solder. Although the basic process of soldering iron and laser welding is the same, the method of providing heated solder is different. Understanding this is crucial.

soldering iron welding process]

|

① Heat the soldering iron tip to about 350°C ② Heat the solder at the joint to the melting temperature (heat transfer) ③ Provide solder |

① Use laser to irradiate the welding part ② Heating of irradiated part (surface heating) ③ Make the surrounding heat conduction to the melting temperature ④ Provide solder |